Standard elementsHMI touch panel – for interactive control of the robot cell

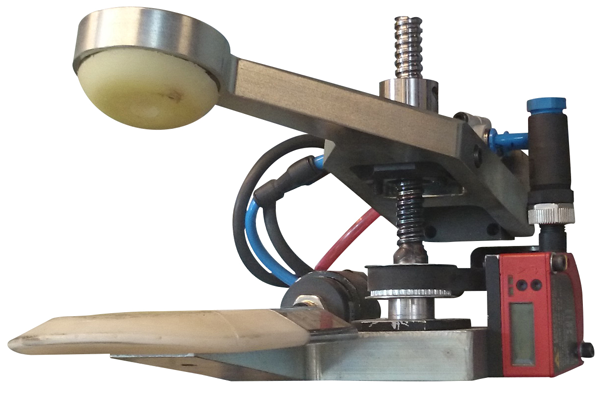

The HMI – Human Machine Interface – is an interactive color touch-screen and a PC. All important settings of Yaskawa Levanto – the speed of Motoman SDA 20, the gripper- and the vibration table settings are controlled via the touch-screen. This allows the operator to control the total sheet handling process based on his personal skills and experiences. All job information can be keyed in via the touch-screen and all relevant job information can be stored as well as a log of all activities. With an appropriate interface job data can be collected from and supplied to the workflow system. Yaskawa lifting table Yaskawa’s lifting table is accessible from two sides. The operator- or the optional conveyor system - can feed the lifting table from one side, while the Motoman SDA 20 robot empties the pile from the other side. Yaskawa Levanto 106s lifting table is configured to handle sheets of up to 76*106 cm and a pile height of up to 135 cm - plus a 15 cm pallet. Versions for higher piles are available on request. The lifting table is equipped with Yaskawa servo-motors and controllers and is controlled by Yaskawa Levanto. The lifting table has lock-bars which prevents sheets from sliding out of position while the Motoman SDA 20 robot manipulates the sheets. Motoman SDA dual-arm humanoid robot The core of the robot-cell is the Motoman SDA 20 robot. In the Yaskawa Levanto 106 cell the Motoman SDA 20 robot can handle sheets between 50*70 cm (28”) and 76*106 cm (41”). It can lift stacks of up to 30 kg and has a cycle time of around 20 seconds – subject to substrate quality. Yaskawa socket The Motoman SDA 20 robot is installed on a vertical socket to allow it to perform a vertical movement of up to 100 cm in Yaskawa Levanto 106. This vertical movement is required to let the Motoman SDA 20 robot lift sheets of the maximum size to a vertical position and deliver the sheets carefully and accurate at the vibration table. Grippers Yaskawa Levanto’s grippers are designed to copy the functions of the human hand. The big lower gripper, which resembles the palm of the hand, has a sharp edge, which carefully separates the wished stack from the pile below. The lower gripper is equipped with ionozised air to prevent anti-static tensions from keeping the sheets together, and a thread pad made of a polymer material prevents marking of the sheets. The area of the lower gripper, which is in contact with the sharp edges of the sheets, is made of stainless steel to prevent wear and tear. The upper gripper, which resembles the thumb, is made of a polymer material and can turn around its axis to prevent marking under pressure. The maximal gripper capacity is 30 mm, but the elaborated stack thickness depends on the quality of the substrate. Vibration table The vibration table is a highly modified standard vibration table from the Baumann group. The total control system is modified by Yaskawa, and all motors are from Yaskawa, so all the vibration table’s functions are controlled by Yaskawa Levanto. Start and stop of the vibration process is controlled by the robot as well as the vibration intensity. The vibration table is equipped with special bars to control the position of the sheets during the delivery. The vibration table can be operated manually in case the operator wants to handle jobs in a specific way. |

|

|

|||

|

|